Additive Manufacturing

We utilize several types of 3D printing technologies for rapid prototyping of parts as well as low-volume manufacturing from a variety of materials.

Fused Deposition Modeling (FDM)

Great for creating prototypes out of the widest variety of ridged and flexible industry thermoplastics including Polylactic Acid (PLA), Acrylonitrile Butadiene Styrene (ABS), Polyethylene Terephthalate Glycol (PETg), Nylon (PA), Thermoplastic Polyurethane (TPU), and Polycarbonate (PC).

Stereolithography (SLA)

A liquid, resin-based 3D printing technology that provides the highest resolution prints. Parts can be produced from a selection of resins created for specialty situations from flexible silicone mimicking, durable impact resistance, high temperature applications, ESD-safe for electronics, to bio-compatible materials for the medical industry. This technology can be used for general prototyping as well as low-volume manufacturing across many industries including jewelry, dental, and medical.

Selective Laser Sintering (SLS)

The fastest 3D printing technology available for functional, durable prototypes and low-volume manufacturing of end-use parts made from Nylon.

Design for Manufacturability

Early prototypes can be refined by going through a design for manufacturing exercise wherein the design is broken down and manipulated to be cost effectively produced by the intended end manufacturing process while maintaining functionality of key design features. The industrial manufacturing processes for which we have the in-house capability in rapid creation for proof-of-concept parts includes:

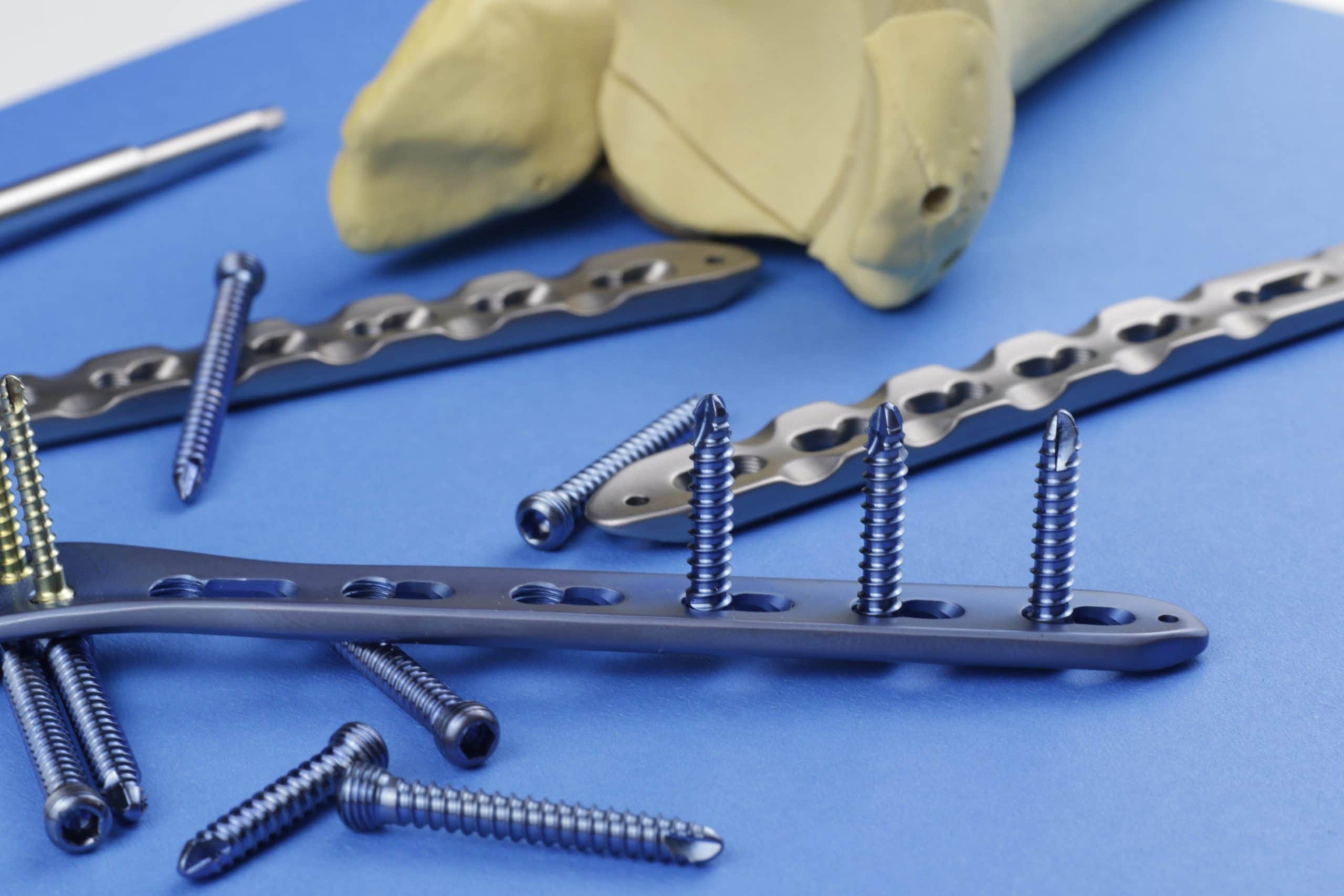

CNC Machining

5-axis Milling and Lathe Turning capabilities from metals and plastics such as Titanium, Stainless Steel, Aluminum, and PEEK

Plastic Injection Molding

Small part injection molding capabilities using rapidly iterated and created 3D printed molds for proof-of-concept parts as well as low-volume manufacturing prototype molds milled from aluminum. Standard industry plastics can also be utilized, including Polypropylene (PP), Polyethylene (PE), Nylon (PA), Acrylonitrile Butadiene Styrene (ABS), Polycarbonate (PC), High Density Polyethylene (HDPE), and Cyclic Olefin Copolymer (COC).

Silicone Injection Molding

3D printed or machined molds can be made for silicone parts or overmolding applications. We work with hobby, food, and class VI medical grade silicones which span the durometer scale from shore hardness 00-10 to 80A.

Product Packaging

Dependent on product needs, we can create custom packaging systems consisting of flexible heat seal packaging or hard-shell vacuum form packaging.